time:Feb 25, 2025 source:ZEXCIT

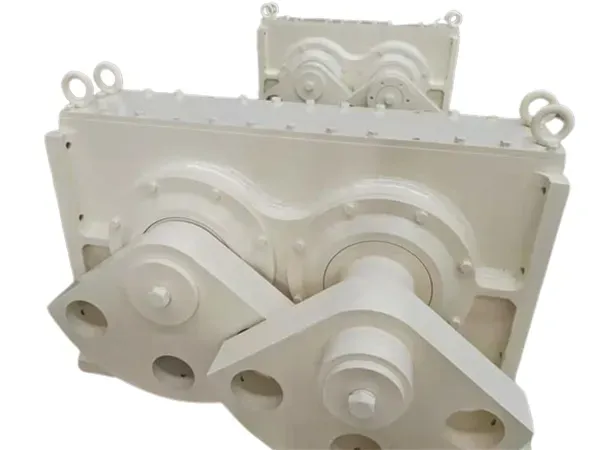

Vibrating screen exciter plays a vital role in industrial production, petroleum, chemical, construction materials and other fields have its appearance, and vibrating screen exciter can be widely used in a number of industries, thanks to its significant advantages.

1. Simple and economic: vibrating screen exciter structure is simple, easy to install, low maintenance costs. It can be quickly put into use in different environments, and maintain a good operating condition.

2. Stable and reliable: vibrating screen exciter has a long service life, and has constant vibration performance and screening effect during long-term use, which brings continuous economic benefits for users.3. Efficient and flexible: the vibrating screen exciter has high screening efficiency and precision. It can be adapted to local conditions, motorized adjustment of vibration parameters, to achieve efficient screening operations.

However, if you do not understand the impact of vibrating screen exciter factors, perhaps it will affect the use of equipment and subsequent production progress. So what are the factors that will affect the operation of the vibrating screen exciter?

1. Power supply failure: the power supply voltage is too high or too low will lead to the shaker can not work properly, or even damage the motor. In addition, poor contact or broken power lines can also lead to shaker failure.

2. Motor failure: motor overload or insulation failure will affect the normal operation of the shaker. Motor overload is usually caused by the vibrating screen load is too large, while the motor insulation aging or burned out will directly affect the performance of the shaker.

3. Failure of the vibrating screen itself: the vibrating screen mesh is damaged or badly worn, which will lead to a reduction in screening efficiency and affect the working effect of the shaker. In addition, the irrational structure of the vibrating screen or poor installation will also lead to exciter failure.

4. Specific problems of electromagnetic vibrating screen: for electromagnetic vibrating screen, the reasons for the exciter not vibrating may include poor coil grounding, coil damage, breakdown of high frequency screen special module, excessive current leading to fuse burnout and so on. These problems need to be solved by testing and replacing the relevant parts.5. Bearing problems: bearing selection is unreasonable, lubrication seal structure design is unreasonable, bearing and bearing hole with improper selection will lead to frequent damage to the bearing. Selection of appropriate bearing type, improvement of lubrication design and reasonable fit selection is the key to solving these problems.

Read the core advantages of vibrating screen exciter in one article

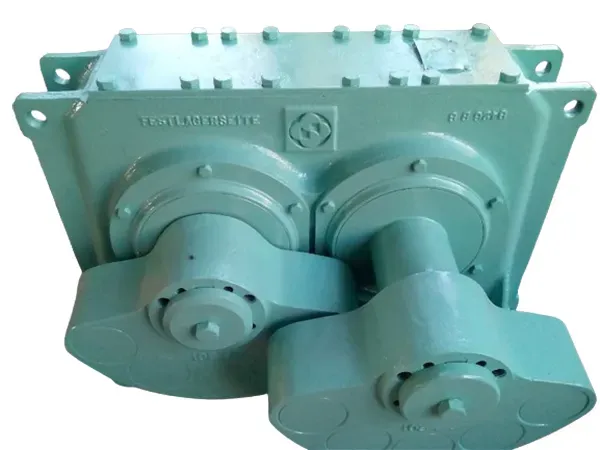

System Analysis HB55 Series Vibrating Screen Exciter

ZSK eccentrics series linear vibrating screen is a new and efficient universal screening equipment, screen box trajectory which is approximately a straight line. This series of screen machine embodies most of the advantages of a biaxial linear screen, with the most extensive scope and application prospects.

READ MORE

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

A flip flop vibrating screen is a type of vibrating screen that utilizes the principle of elasticity to effectively screen and separate fine materials. This unique design creates a flip-flop motion during the screening process, which helps prevent material blinding and pegging.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.