time:Feb 22, 2025 source:ZEXCIT

The main role of the shaker is to make the sieve vibration, the force generated by the sieve to a specific frequency and amplitude vibration, so as to classify or separate the material according to the size. From a productivity standpoint, vibrating screen exciters significantly increase capacity and drive up the level of production automation. By accurately controlling the frequency and amplitude of the vibration of the screen, the shaker is able to efficiently sort materials by size, a process that not only dramatically shortens the production cycle, but also significantly enhances the company's production efficiency compared to traditional manual screening methods. What's more, the shaker supports regular and quantitative screening operations, which is highly controllable to ensure the stability and continuity of the production process, further enhance the overall work efficiency, and create greater economic benefits for the enterprise.

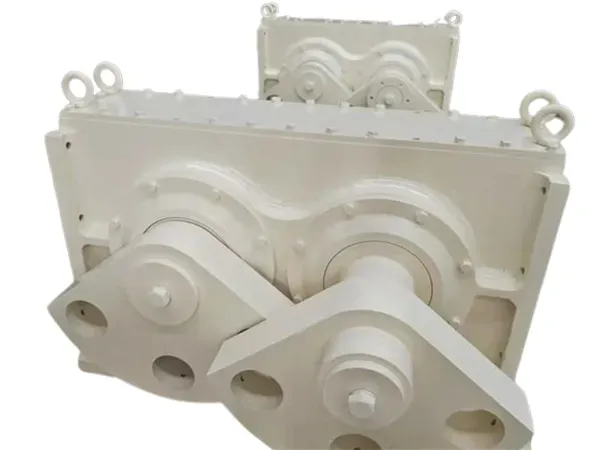

The performance and reliability of the shaker is crucial to the continuous operation of the vibrating screen. The shaker must withstand harsh operating conditions, including heavy loads, constant vibration and high environmental stress, while maintaining optimal vibration performance. The shaker adopts Schenker technology, no ventilation cap, completely preventing dust or foreign objects from entering the shaker; the gas and heat inside the shaker can be exchanged freely with the outside world through the special sealing device between the shaft and the shaft, no lubricant leakage; the magnetic oil plug absorbs the fine metal particles inside the exciter, effectively protects all the rotating parts inside the exciter from being damaged, and improves the reliability and safety of the equipment.

Vibrating screen exciter also shows significant advantages in energy saving and environmental protection. Its shell adopts advanced ductile iron thin-wall casting process, this innovation not only reduces material waste, simplifies the sand treatment system, but also reduces casting defects and realizes the effect of fine casting, thus replacing to a certain extent the complex and energy-consuming fine casting process. In addition, through the optimization of the vibration structure, the noise generated by the shaker in the operation process has been effectively controlled, reducing the interference with the operator and the surrounding environment, reflecting the high importance of environmental protection and humanistic care.

With the continuous progress and innovation of science and technology, vibrating screen exciter has become an indispensable part of production by virtue of its core advantages of capacity enhancement, performance optimization, energy saving and environmental protection and noise reduction. Looking to the future, vibrating screen exciter will continue to lead the industry forward, constantly breakthrough innovation, for the continuous progress of industrial production and green development to create more value to create more value.

Vibrating Screen Exciter Model Details

Don't let these factors affect the operation of vibrating screen exciter

ZSK eccentrics series linear vibrating screen is a new and efficient universal screening equipment, screen box trajectory which is approximately a straight line. This series of screen machine embodies most of the advantages of a biaxial linear screen, with the most extensive scope and application prospects.

READ MORE

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

A flip flop vibrating screen is a type of vibrating screen that utilizes the principle of elasticity to effectively screen and separate fine materials. This unique design creates a flip-flop motion during the screening process, which helps prevent material blinding and pegging.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.