time:Jan 23, 2025 source:ZEXCIT

The exciter is the heart of a vibrating screen. It's the mechanism responsible for generating the vibratory motion that allows the screen to separate materials by size. Without a functioning exciter, the screen would be stationary and useless.

There are several types of exciters, each with its own characteristics and applications. The most common include:

How They Work: These exciters utilize rotating eccentric weights (usually two or four) attached to a shaft. The rotation of these unbalanced weights creates a centrifugal force that causes the screen to vibrate in a circular motion.

Characteristics:

Simple Design: Relatively straightforward and robust.

Cost-Effective: Typically less expensive than other types.

Easy to Maintain: Parts are often readily available.

Circular Motion: The screen moves in a circular or elliptical path, which is effective for general screening applications.

Amplitude & Frequency Adjustment: Adjustment of the weights and rotational speed changes the amplitude and frequency of the vibration.

Applications: Widely used for general screening, crushing, and sizing in mining, quarrying, and construction industries.

How They Work: These exciters typically use a counter-rotating pair of shafts with offset weights. By adjusting the phase angle between the rotating weights, the motion is directed into a linear or near-linear path.

Characteristics:

Directed Motion: The screen primarily moves back and forth, rather than in a circle.

Effective for Dewatering: The linear motion is efficient at moving materials forward, making them suitable for dewatering applications.

Higher Efficiency: Generally more efficient than circular motion exciters for certain applications.

More Complex Design: More intricate than circular motion exciters, potentially leading to higher maintenance costs.

Applications: Used in dewatering, washing, and conveying materials, particularly in the aggregate and mineral processing industries.

How They Work: These exciters use an electromagnet to induce vibration in the screen. They often employ a spring system and a magnetic core to produce the vibration.

Characteristics:

Adjustable Frequency: Easily adjustable frequency for optimal separation.

Precise Control: Offer very precise control over the amplitude and frequency.

Low Noise Levels: Generally quieter than mechanical exciters.

Sensitive to Environment: May be affected by dust, moisture, or temperature extremes.

Lower Force Output: Typically have a lower force output compared to mechanical exciters.

Applications: More specialized applications, including laboratory testing, fine particle screening, and applications where precise control is required.

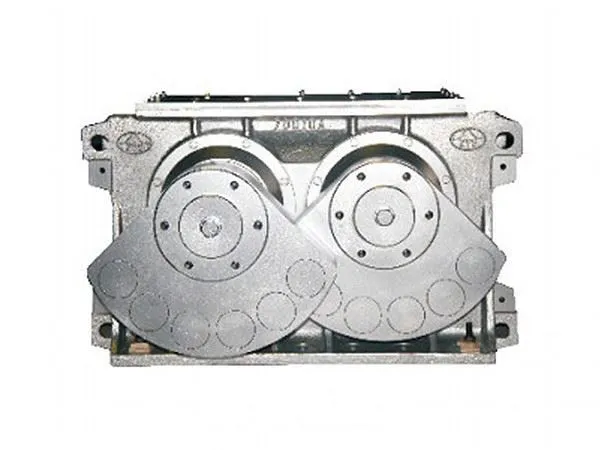

Shafts: Heavy-duty, hardened steel shafts that support the rotating eccentric weights.

Bearings: Robust bearings to handle the high loads and vibration. Typically, spherical roller bearings are used due to their ability to accommodate misalignment and high loads.

Eccentric Weights: Cast iron or steel weights that are carefully machined and balanced. They are adjustable to control the force of vibration.

Housings: Sturdy housings that enclose and protect the internal components, ensuring proper lubrication and sealing.

Lubrication System: Typically, a grease or oil lubrication system is used to reduce friction and wear on moving parts. This can be a manual or automatic system.

Seals: To prevent ingress of dust, dirt, and moisture, ensuring proper operation and longevity.

Fasteners: Bolts, nuts, and locking mechanisms that hold the entire exciter together securely.

Screen Size & Capacity: The size and capacity of the screen will dictate the force required from the exciter.

Material Being Screened: The material properties (density, size, shape) will impact the type and settings of the exciter.

Application: Dewatering, sizing, or other specific applications will require different exciter characteristics.

Budget: Different types of exciters come with varying price points.

Maintenance & Reliability: Consider ease of maintenance and the expected lifespan of the exciter.

Operating Environment: Environmental conditions (dust, moisture, temperature) will affect the selection of bearings, seals, and lubrication.

Regular Inspection: Conduct routine checks for loose bolts, worn bearings, and any signs of damage.

Lubrication: Follow the manufacturer's recommendations for lubrication, using appropriate grease or oil.

Bearing Replacement: Replace bearings as needed, typically based on operating hours.

Weight Adjustment: Periodically check and adjust eccentric weights to ensure proper balance and vibration force.

Seal Inspection & Replacement: Replace worn or damaged seals to maintain lubrication and prevent contamination.

Torque Checks: Ensure that all bolts are properly torqued to prevent loosening due to vibration.

In summary, the vibrating screen exciter is a critical component that directly impacts the efficiency and effectiveness of the screening process. Understanding the different types of exciters, their components, and their maintenance requirements is essential for optimizing your operations and ensuring reliable performance.

What is the structure of vibrating screen exciter

Read the core advantages of vibrating screen exciter in one article

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

NE Series Vibrators are versatile and reliable components used in a wide range of industrial applications to generate controlled vibrations for material handling, processing, compaction, and testing purposes. Their robust construction, high efficiency, and adjustable settings make them suitable for various industries requiring vibration-based solutions.

READ MORE

The FE series vibrator is a specialized component used in various industrial applications to generate controlled vibrations. These vibrators are designed to be reliable, durable, and efficient, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.