time:Apr 24, 2025 source:ZEXCIT

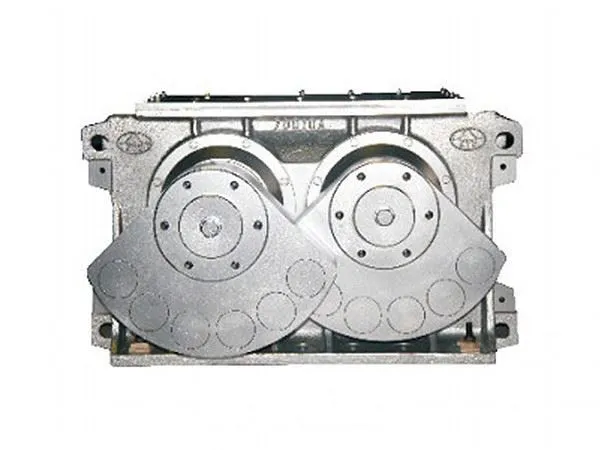

The vibrating screen exciter is a critical component responsible for generating the vibration necessary for material screening. However, during prolonged or heavy-duty operation, the exciter may experience overheating—a common yet serious issue that can affect equipment performance, reduce operational lifespan, and lead to unexpected downtime.

Exciter overheating typically results from factors such as insufficient lubrication, excessive load, bearing failure, or poor maintenance practices. Identifying the root causes and implementing preventive measures are essential to ensure the stable and efficient functioning of vibrating screens in industrial settings. An overheated vibrating screen exciter (also called a vibrator motor or shaker mechanism) is a serious issue that needs immediate attention to prevent catastrophic failure and costly repairs.

STOP THE SCREEN IMMEDIATELY: Do not continue running the screen. Continued operation will likely cause severe damage to bearings, seals, and potentially the entire exciter unit or screen structure.

FOLLOW LOCKOUT/TAGOUT (LOTO) PROCEDURES: Before attempting any inspection or maintenance, ensure the machine is completely de-energized and cannot be accidentally restarted. This is critical for your safety.

ALLOW IT TO COOL DOWN: Let the exciter cool down naturally. Do not try to force cool it with water or compressed air, as this can cause thermal shock and crack components.

Once the unit has cooled down and LOTO procedures are in place, investigate the potential causes:

Check Lubrication (Most Common Cause):

Level: Is the oil level correct (check sight glass or dipstick)? Is the grease level correct (if grease lubricated)? Both too low (starvation) and too high (churning) can cause overheating.

Type: Are you using the correct type and viscosity of oil or grease specified by the screen and/or exciter manufacturer? Using the wrong lubricant is a major cause of overheating and failure.

Condition: Check the lubricant's condition. Is it dark, sludgy, milky (water contamination), or does it smell burnt? This indicates degradation or contamination. Consider taking an oil sample for analysis if possible.

Frequency: When was it last lubricated? Was it according to the manufacturer's recommended schedule?

Inspect Bearings:

Overheating is often a primary symptom of failing bearings. Listen for unusual noises (grinding, rumbling) when the machine was running (if you noticed any) or try carefully rotating the shaft by hand (if possible and safe) to feel for roughness or binding.

Check the bearing housing temperature regularly (using an infrared thermometer) during normal operation as part of preventative maintenance. Compare readings to baseline or manufacturer specs.

Check for Obstructions & Cleanliness:

Is the exciter housing covered in dirt, dust, or built-up material? This can act as an insulator, preventing proper heat dissipation. Clean the exterior thoroughly.

Ensure ventilation openings (if any) are clear.

Check Alignment & Mounting:

Are the exciter mounting bolts tight? Loose bolts can cause misalignment and stress.

If driven by an external motor via belts or a cardan shaft, check the alignment between the motor and the exciter. Misalignment puts excessive load on bearings.

Check Drive System (if applicable):

Belts: Are the drive belts tensioned correctly? Too tight puts excessive load on bearings; too loose can cause slippage and heat. Are the belts worn or damaged?

Sheaves/Pulleys: Are the sheaves worn or damaged? Are they aligned correctly?

Check Operating Conditions:

Overloading: Is the screen being overloaded with material? Is material building up on the screen deck? This increases the load on the exciter.

Ambient Temperature: Is the surrounding air temperature exceptionally high? While exciters are designed for industrial environments, extreme heat combined with other factors can contribute to overheating.

Screen Dynamics: Has anything changed about the screen setup (stroke, speed, counterweights)? Incorrect settings can cause overload.

Based on your findings:

Lubrication: Drain contaminated/degraded lubricant. Flush the system if necessary. Refill with the correct type and amount of fresh lubricant specified by the manufacturer. Correct the lubrication schedule/procedure.

Bearings: If bearings are suspected, they will likely need replacement. This is often a job for experienced technicians or the manufacturer/service provider, as it requires specialized tools and procedures.

Cleanliness: Clean the exciter housing and surrounding area.

Alignment/Mounting: Tighten mounting bolts to the correct torque. Correct any misalignment issues.

Drive System: Adjust belt tension, replace worn belts or sheaves.

Operating Conditions: Address overloading issues, clear material buildup, ensure proper screen setup.

If you cannot identify the cause.

If bearing replacement is required and you don't have the expertise/tools.

If you suspect internal damage to the exciter.

If the problem persists after taking corrective actions.

If you are unsure about any step.

Key Takeaway: Overheating is a critical warning sign. Stop the machine immediately, ensure safety, and systematically investigate the cause, starting with lubrication. Always refer to your specific vibrating screen's operation and maintenance manual for detailed instructions and specifications.

Vibrating Screen Exciter Installation Guide

No information

ZSK eccentrics series linear vibrating screen is a new and efficient universal screening equipment, screen box trajectory which is approximately a straight line. This series of screen machine embodies most of the advantages of a biaxial linear screen, with the most extensive scope and application prospects.

READ MORE

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

A flip flop vibrating screen is a type of vibrating screen that utilizes the principle of elasticity to effectively screen and separate fine materials. This unique design creates a flip-flop motion during the screening process, which helps prevent material blinding and pegging.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.