time:Jan 23, 2025 source:ZEXCIT

The structure of a vibrating screen exciter is crucial for its performance and reliability. While specific designs can vary between manufacturers and applications, the core components and their functions remain consistent. Here's a breakdown of the typical structure of a vibrating screen exciter:

Eccentric Shaft (or Shaft Assembly):

Function: This is the heart of the exciter. It's a rotating shaft with deliberately offset weights or an eccentric profile. As the shaft rotates, the offset mass creates a centrifugal force. This force is what generates the vibrations that drive the screen deck.

Construction: Typically made of high-strength steel, precisely machined for balance and durability. It often has bearing journals for supporting bearings and threaded portions for attaching counterweights or eccentric members.

Types:

Circular Eccentric Shaft: The simplest type, with a circular offset mass. Provides a consistent circular motion.

Adjustable Eccentric Shaft: Allows for altering the eccentricity (amount of offset) to change the vibration amplitude. This can be done by adding or repositioning weights or adjusting the eccentric mechanism.

Linear Eccentric Shaft: Uses specially shaped cams to generate more linear vibrations, suitable for certain applications.

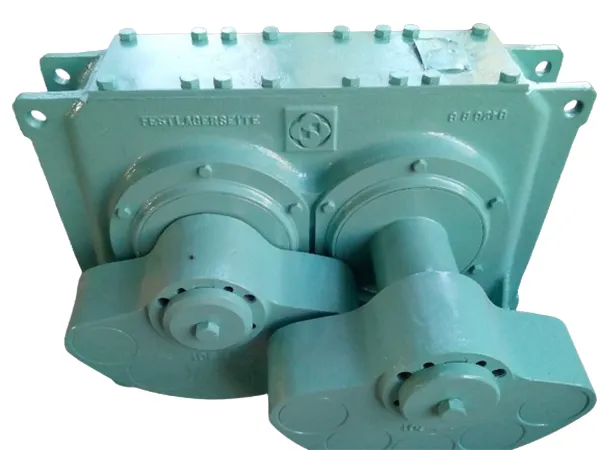

Bearing Housings and Bearings:

Function: These components support the rotating eccentric shaft, allowing for smooth and low-friction rotation. They also must withstand the substantial vibrations and forces generated by the exciter.

Construction: The housings are typically made of robust cast iron or steel, precisely machined to hold the bearings in alignment. They are often bolted securely to the screen body or exciter frame. The bearings are usually heavy-duty, often spherical or cylindrical roller bearings designed for high loads and vibration.

Lubrication: Bearings are usually lubricated with grease or oil, and are typically sealed to protect them from contaminants. Regular lubrication is critical to prevent premature failure.

Eccentric Weights (or Eccentric Members):

Function: These are the offset masses that, when rotated, create the vibrating force.

Construction: They are typically made of cast iron or steel and are precisely balanced to ensure smooth operation. They can be fixed to the eccentric shaft, or adjustable for changing the amplitude of vibration.

Types:

Fixed Weights: Offer a consistent vibration force.

Adjustable Weights: Allows for fine-tuning the vibration amplitude by changing the mass or position of the weights.

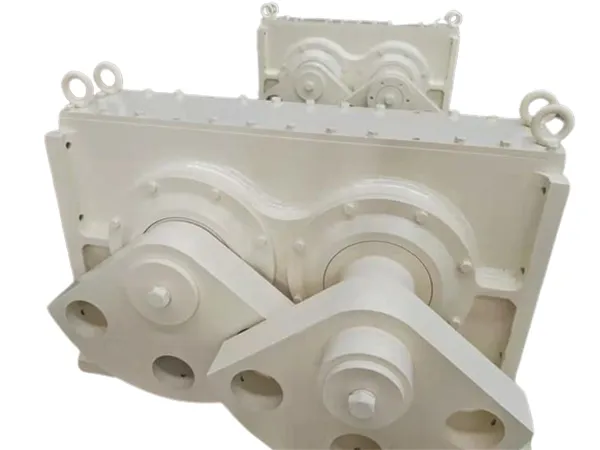

Exciter Frame (or Housing):

Function: This is the structural frame that holds all the other components together and provides a mounting point for the screen deck.

Construction: Typically made of welded steel for strength and rigidity. It's designed to withstand the vibrations and transmit the vibration forces to the screen body.

Mounting: The exciter frame is bolted to the screen body, often with vibration dampeners to reduce the transmission of vibrations to the surrounding structure.

Drive System (Motor and Coupling):

Function: This system provides the rotational power to the eccentric shaft.

Components:

Electric Motor: Usually a robust induction motor that's designed to operate under vibration.

Coupling: Connects the motor shaft to the exciter shaft. Couplings are designed to accommodate slight misalignments and reduce vibration transmission. Various types are used, including flexible couplings, fluid couplings, and V-belt drives.

Sometimes: Includes a gear box or other speed reducing mechanism if the motor speed is too high.

(Sometimes) Oil Bath or Lubrication System:

Function: In some exciter designs, especially for heavy-duty applications, a closed lubrication system with an oil bath is used to provide constant lubrication and cooling to the bearings.

Components: May include an oil reservoir, pump, filters, and piping.

The electric motor rotates the eccentric shaft through a coupling mechanism.

The rotation of the eccentric shaft with its offset weights or eccentric profile creates a centrifugal force.

This force generates a vibrating motion that is transmitted to the exciter frame and then to the screen deck.

The screen deck vibrates, causing the material on the screen to move and stratify.

Key Design Considerations:

Vibration Frequency and Amplitude: The design must ensure the desired vibration frequency and amplitude are achieved for efficient screening.

Strength and Durability: The exciter needs to be robust enough to withstand the constant vibrations and mechanical stresses.

Balance and Smooth Operation: The exciter must be precisely balanced to prevent excessive vibrations and premature failure.

Maintenance Accessibility: The design should allow for easy access for lubrication and maintenance.

Circular Motion Exciters: The most common type, producing a circular or near-circular motion. Suitable for a wide range of applications.

Linear Motion Exciters: Produces a linear motion, typically used for dewatering and specific material types.

Elliptical Motion Exciters: Produces a more complex elliptical motion that offers advantages in certain applications.

In summary, a vibrating screen exciter is a carefully engineered assembly designed to convert rotational motion into vibratory motion. Its structure includes a rotating eccentric shaft, supported by bearings, with weights that generate the vibrating force. Understanding these components is essential for selecting, maintaining, and troubleshooting vibrating screens.

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

NE Series Vibrators are versatile and reliable components used in a wide range of industrial applications to generate controlled vibrations for material handling, processing, compaction, and testing purposes. Their robust construction, high efficiency, and adjustable settings make them suitable for various industries requiring vibration-based solutions.

READ MORE

The FE series vibrator is a specialized component used in various industrial applications to generate controlled vibrations. These vibrators are designed to be reliable, durable, and efficient, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.