time:Mar 14, 2025 source:ZEXCIT

The vibrating screen exciter is a crucial component in vibrating screens, responsible for generating the necessary vibration to separate materials. The working principle of the exciter is based on unbalanced forces created by rotating masses. The working principle of a vibrating screen exciter revolves around converting rotational motion into vibratory motion. This vibratory motion is then transmitted to the screen deck, causing the material on the screen to stratify and separate based on size.

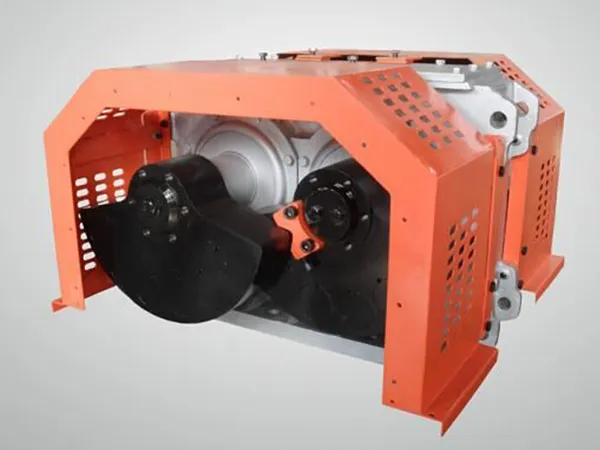

Eccentric Weights (Unbalanced Masses): These are the key elements. An exciter typically contains one or more pairs of eccentric weights attached to a rotating shaft. "Eccentric" means the center of mass of the weight is not aligned with the axis of rotation.

Shaft: A rotating shaft, usually driven by an electric motor through a belt or direct coupling.

Bearings: Support the rotating shaft and allow for smooth, low-friction operation.

Housing/Frame: Encases and protects the internal components and provides mounting points to the vibrating screen.

Lubrication System: Essential for maintaining bearing life and reducing friction. This can be grease-based or oil-based.

Rotation: The electric motor drives the shaft to rotate.

Centrifugal Force Generation: As the eccentric weights rotate, they generate centrifugal force. The magnitude of this force is proportional to the mass of the eccentric weight, the square of the rotational speed, and the distance of the weight's center of mass from the axis of rotation. The formula is: F = m * r * ω² where:

F = Centrifugal Force

m = Mass of the eccentric weight

r = Distance from the center of mass of the eccentric weight to the axis of rotation (the eccentricity)

ω = Angular velocity (rotational speed in radians per second)

Vibration Direction & Amplitude Control:

Angle of Eccentric Weights: The position of the eccentric weights relative to each other is crucial. By adjusting the angle between the weights, you can control the direction and type of vibration.

Circular Motion: If two eccentric weights are positioned opposite each other on the shaft, the centrifugal forces combine to create a circular or near-circular motion.

This is common in circular motion vibrating screens.

Linear Motion: If the eccentric weights are synchronized (aligned or close to aligned), the centrifugal forces mainly combine to produce linear vibration. This is seen in linear motion vibrating screens. The angle also impacts the vibration direction.

Magnitude of Eccentric Weights & Speed: The size of the eccentric weights and the speed of rotation directly impact the amplitude (the size of the vibration). Larger weights or higher speeds create larger vibrations.

Force Transmission: The vibratory force generated by the rotating eccentric weights is transmitted through the exciter's housing to the screen deck. The exciter is rigidly connected to the screen frame to ensure efficient transfer.

Screen Deck Vibration: The vibrating force causes the screen deck to vibrate. This vibration has a specific frequency and amplitude depending on the design and settings of the exciter.

Material Stratification and Separation: The vibration of the screen deck causes the material on the screen to stratify. Smaller particles fall through the screen openings, while larger particles remain on top. The vibration also helps to prevent blinding (where particles clog the screen openings).

Different types of exciters produce different vibration patterns

Circular Motion Exciters (Vibrating Screens): Generate a circular or near-circular motion. These are often used for general-purpose screening and scalping applications. Typically use two eccentric weights rotating in opposite directions.

Linear Motion Exciters (Linear Motion Screens): Produce a linear back-and-forth motion. These are often used for dewatering, conveying, and fine particle separation. The stroke direction is typically adjustable.

Elliptical Motion Exciters: Generate an elliptical motion, which is a combination of circular and linear motion. These are less common but can be used for specific applications.

Self-Synchronizing Exciters: These exciters use two or more eccentric weights that automatically synchronize their rotation to achieve a stable vibration pattern. This is often achieved through gearing or other mechanical linkages.

Amplitude Adjustment: Often achieved by changing the effective mass of the eccentric weights. This can be done by adding or removing weights or by adjusting the position of adjustable weights.

Frequency Adjustment: Controlled by changing the motor speed, often using a Variable Frequency Drive (VFD).

Lubrication: Regular lubrication of bearings is critical for long exciter life.

Regular Inspection: Inspecting for loose bolts, cracks, and unusual noises is important for preventative maintenance.

Balancing: Over time, the exciter can become unbalanced due to wear or damage. Balancing is necessary to ensure smooth operation and prevent damage.

In summary, a vibrating screen exciter works by using rotating eccentric weights to generate centrifugal forces. These forces are converted into vibratory motion, which is transmitted to the screen deck to stratify and separate materials based on size. The design and adjustment of the eccentric weights determine the type of vibration (circular, linear, or elliptical) and its amplitude, which are crucial for optimizing screening performance.

System Analysis HB55 Series Vibrating Screen Exciter

What is the impact of vibrating screen exciter on screening efficiency

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

NE Series Vibrators are versatile and reliable components used in a wide range of industrial applications to generate controlled vibrations for material handling, processing, compaction, and testing purposes. Their robust construction, high efficiency, and adjustable settings make them suitable for various industries requiring vibration-based solutions.

READ MORE

The FE series vibrator is a specialized component used in various industrial applications to generate controlled vibrations. These vibrators are designed to be reliable, durable, and efficient, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.