Electromagnetic vibratory feeders operate using the cyclic energization of one or more electromagnets. In comparison with electromechanical drives, electromagnetic drive units contain lesser moving parts. The trough is caused to vibrate using the magnetic force impulses supplied by the electromagnet. In terms of cost, electromagnetic feeders are cheaper for low-volume applications. This is true at rates less than 5 tons per hour.

READ MORE

Robust vibrating feeders, also known as heavy-duty vibrating feeders, are designed to handle demanding applications in industries where durability, reliability, and high-performance operation are essential. These feeders are engineered to withstand harsh conditions, heavy loads, and abrasive materials.

READ MORE

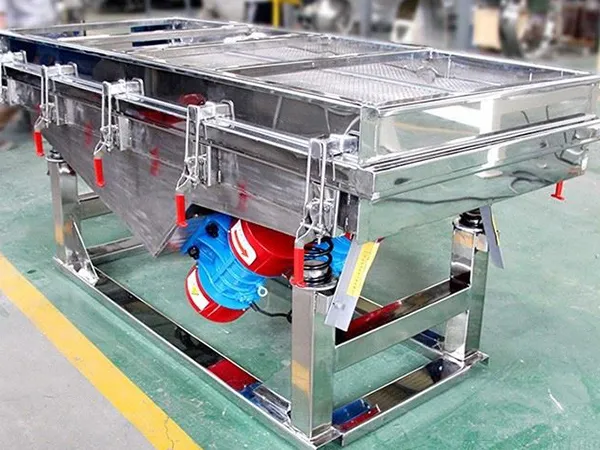

Our vibrating troughs, with a maximum conveying distance of approximately 8 meters, are designed as free-vibrating machines consisting of elastically supported conveying troughs coupled to vibration motors or electromagnetic vibrators. Machined saddles on the drive ensure continuous, maintenance-free operation.

READ MORE

The vibratory storage feeder operates on the principle of vibration-induced motion. As the trough vibrates, the material inside experiences forces that cause it to move along the trough's length. This movement can be controlled by adjusting the frequency and amplitude of the vibrations.

READ MORE

During the production of plastic pellets, especially during the start-up and shut-down phases, wrong cuts in the form of spikes or chains (often referred to as oversize) can occur. These bad particles interfere with further processing and must be separated from good particles.

READ MORE

Quartz sand screening equipment is essential in the processing of quartz sand to separate and classify particles of different sizes. These equipments ensure that the quartz sand meets the required specifications for various applications, including glassmaking, foundry work, ceramics, construction, and abrasives.

READ MORE

The finger screen vibrating separators are effective solutions for screening and separating difficult-to-handle materials in various industries. Their unique finger design, high-amplitude vibration, and self-cleaning action make them well-suited for applications where conventional vibrating screens may struggle to perform effectively.

READ MORE

The single deck horizontal screens offer efficient and reliable screening solutions for a wide range of industrial applications. Their horizontal deck arrangement, vibration mechanism, and adjustability make them suitable for optimizing screening operations and achieving high throughput capacity with excellent screening efficiency.

READ MORE

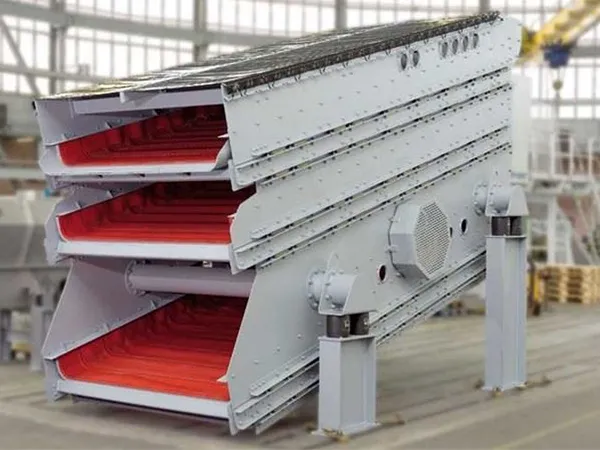

The double deck horizontal screens offer efficient and reliable screening solutions for various industrial applications. Their horizontal deck orientation, combined with high-capacity screening capabilities, makes them ideal for optimizing screening operations and achieving high throughput capacity with excellent screening efficiency.

READ MORE

The double deck banana screens offer efficient and reliable screening solutions for bulk materials, thanks to their unique banana-shaped deck design, high-frequency vibration mechanism, and versatility. Their enhanced screening efficiency makes them suitable for optimizing screening operations in various industries.

READ MORE

Single deck banana screens are specialized types of vibrating screens commonly used in the mining and aggregate industries for efficient screening of bulk materials.

READ MORE

The gravity flow design of the gravity flow vibrating screen features a twenty-degree downslope for gravity-assisted product conveying. Each rotary electric vibrator is driven by a single motor or exciter.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.