A vibrating tube-type feeder, also known as a vibratory tube feeder or tube conveyor, is a specialized type of vibrating feeder used for conveying bulk materials in a tube-shaped structure. These feeders are commonly used in industries such as food processing, pharmaceuticals, chemicals, and plastics, where gentle handling of materials and sanitary conditions are essential.

READ MORE

A hopper discharging system, also known as a hopper discharge system or hopper unloading system, is a mechanism used to efficiently and reliably empty or discharge materials from a storage hopper or bin. These systems are commonly used in various industries such as mining, agriculture, manufacturing, and bulk material handling.

READ MORE

Coal vibrating feeders are used to convey bulk materials from hoppers, silos, crushers, etc. in a wide range of applications including chemical, coal, foundry, quarrying and steel industries. The coal vibrating feeders produced by our company range in capacity from 100 tons/hour to 2500 tons/hour.

READ MORE

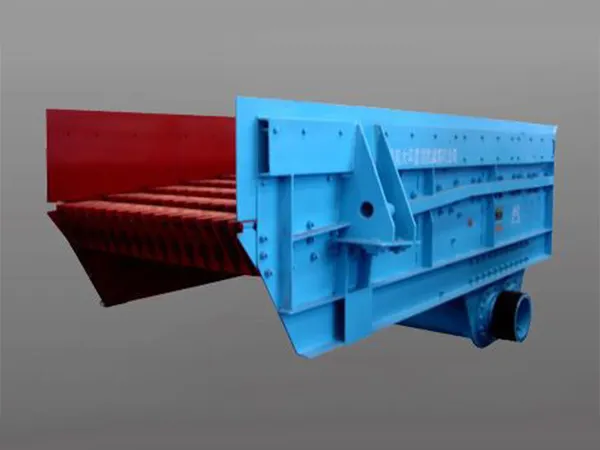

The K-type reciprocating stoker vibrating feeder is used to feed coal or other loose granular materials with low abrasion and low viscosity, and continuously and uniformly discharge the materials in the storage bin or pit to the transportation equipment or other screening equipment.

READ MORE

A vibrating tubular feeder, also known as a tubular conveyor or tubular vibratory feeder, is a specialized type of vibrating feeder used for conveying bulk materials in a tube-shaped structure.

READ MORE

Plate vibrating feeders offer efficient and reliable material handling solutions for industries requiring controlled feeding of bulk materials or parts along a linear conveyor path. Their robust construction, versatility, and adjustability make them suitable for a wide range of applications in diverse industrial settings.

READ MORE

Dosing vibrating feeders play a crucial role in various industries where accurate and reliable material dosing is critical for product quality, process efficiency, and regulatory compliance.

READ MORE

Furnace charge feeder ,ZG series vibrating feeder is a new type, energy-saving general feeding equipment. The machine adopts a new type of vibration motor as the excitation source, which has the advantages of simple and compact structure, convenient use and maintenance, continuous and uniform feeding, small wear on the trough, and long service life.

READ MORE

Heavy-duty vibrating feeders are essential equipment in industries where reliable and efficient material handling is critical. Their rugged construction, high-performance capabilities, and versatility make them suitable for a wide range of demanding applications.

READ MORE

Electromagnetic vibratory feeders operate using the cyclic energization of one or more electromagnets. In comparison with electromechanical drives, electromagnetic drive units contain lesser moving parts. The trough is caused to vibrate using the magnetic force impulses supplied by the electromagnet. In terms of cost, electromagnetic feeders are cheaper for low-volume applications. This is true at rates less than 5 tons per hour.

READ MORE

Robust vibrating feeders, also known as heavy-duty vibrating feeders, are designed to handle demanding applications in industries where durability, reliability, and high-performance operation are essential. These feeders are engineered to withstand harsh conditions, heavy loads, and abrasive materials.

READ MORE

Our vibrating troughs, with a maximum conveying distance of approximately 8 meters, are designed as free-vibrating machines consisting of elastically supported conveying troughs coupled to vibration motors or electromagnetic vibrators. Machined saddles on the drive ensure continuous, maintenance-free operation.

READ MOREVibrating feeders use a vibration mechanism to move materials. This mechanism is typically powered by an electric motor with an eccentric weight attached to the motor's shaft. The rotation of the eccentric weight generates vibration in a specific direction, causing the feeder to vibrate.

The material is contained in a tray or trough that vibrates along with the feeder. The tray or trough is typically made of durable materials to withstand the impact of the materials being conveyed.

The drive unit consists of the motor and the associated components that generate the vibration. It can be either electromagnetic (using an electromagnetic coil) or mechanical (using an eccentric weight on a rotating shaft).

Vibrating feeders often have a control system to regulate the flow of material. The control system can be manual or automated, allowing for adjustments to the vibration intensity and frequency.

The vibrating feeder is typically mounted on a support structure to ensure stability during operation.

Consistent and controlled material flow. Reduced wear and tear on downstream equipment. Efficient handling of various types of materials, including abrasive or sticky substances.

The vibrating feeder is equipped with a vibrating drive that generates vibrations with a specific amplitude and frequency. This drive can be an electromagnetic coil, a motor with unbalanced weights, or another source of vibration.

The bulk material to be conveyed is placed on a tray or trough that is attached to the vibrating drive. The tray is typically supported by springs or other damping elements to allow for controlled movement.

The vibration generated by the drive is transmitted to the tray or trough, causing it to vibrate. The vibrations move the material along the tray in a controlled manner.

As the tray vibrates, the bulk material is propelled forward in a series of small jumps or motions. The amplitude and frequency of the vibrations are carefully controlled to ensure a smooth and consistent material flow.

Vibrating feeders often have adjustable parameters such as amplitude and frequency to accommodate different types of materials and control the feed rate. These adjustments allow for customization based on the specific requirements of the application.

The vibrating feeder may include a control system that allows operators to adjust the parameters and monitor the performance of the feeder. Sensors may be used to provide feedback on the material level in the feeder tray or other relevant parameters.

Vibrating feeders find applications in a variety of industries, including mining, construction, chemical, and manufacturing. They are used to feed materials into crushers, screens, or other processing equipment in a controlled and efficient manner.

CONTACT US

Our team of experts are ready to help find you solutions tailored to your specific needs.

Contact Us TodayCopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.