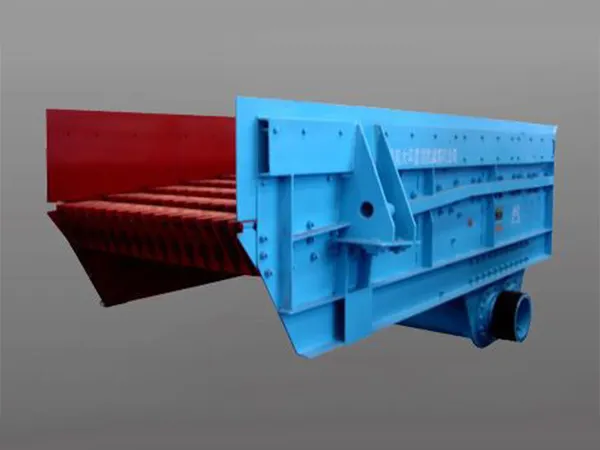

A heavy-duty vibrating feeder is a robust piece of equipment designed to handle high-capacity and demanding applications in industries such as mining, aggregates, construction, and recycling. These feeders are engineered to withstand heavy loads, abrasive materials, and harsh operating conditions.

Robust Construction: Heavy-duty vibrating feeders are built with sturdy materials such as steel or reinforced alloys to withstand the rigors of heavy loads and abrasive materials.

Reinforced Components: Critical components such as troughs, springs, bearings, and drive units are reinforced or specially designed to handle heavy loads and ensure durability.

High-Capacity Design: These feeders are capable of handling large volumes of material, making them suitable for applications requiring high throughput rates.

Adjustability: They often feature adjustable settings for vibration intensity, frequency, and amplitude to accommodate different types of materials and processing requirements.

Protection Measures: Heavy-duty vibrating feeders may include protective measures such as guards, covers, and sealing mechanisms to prevent damage from dust, moisture, and other environmental factors.

1. The principle design of the excitation force generated by the shaft eccentric vibration is adopted.

2. The vibration is stable, the feeding is continuous and uniform, and the production line is balanced.

3. At the same time of feeding, the fine material can be pre-screened to improve the crushing efficiency.

4. The structure design with adjustable screen gap can effectively prevent the material from clogging.

5. Optional speed-regulating motor, by adjusting the frequency, it is convenient to control the feeding amount, and there is no need to start the motor frequently.

6. Low noise in the working process, which is conducive to improving the working environment.

7. High efficiency, large feeding capacity, convenient installation and maintenance, and low operating cost.

Vibration Generation: Heavy-duty vibrating feeders typically utilize powerful motors or electromagnets to generate intense vibrations. These vibrations are transmitted to the feeder trough, causing the material to move along the conveyor path.

Material Handling: As the feeder trough vibrates, the bulk material or particles placed on it are conveyed forward in a controlled manner. The amplitude, frequency, and angle of vibration can be adjusted to optimize material flow and prevent clogging or jamming.

Orientation: In some applications, heavy-duty vibrating feeders are used to orient materials by controlling the direction and intensity of the vibrations. This ensures that the materials are properly aligned for downstream processes.

Discharge: At the discharge end of the feeder, mechanisms such as gates, chutes, or conveyor belts regulate the flow of material onto the next stage of the production process.

| Model | Input(mm) | Speed(r/min) | Capcity(t/h) | Power(kw) | Outline(mm) |

| ZSW380×95 | 500 | 500-800 | ~150 | 11 | 3970×2259×1880 |

| ZSW420×110 | 580 | 500-800 | 150-280 | 15 | 4392×2519×2003 |

| ZSW490×110 | 580 | 450-800 | 150-350 | 18.5 | 5093×2545×2014 |

| ZSW600×130 | 750 | 500-800 | 220-560 | 30 | 6124×2863×2051 |

| ZSW600×150 | 900 | 500-800 | 260-620 | 37 | 6271×2369×2698 |

| ZSW600×180 | 1050 | 600-800 | 400-1000 | 45 | 6268×2653×3097 |

| ZSW600×210 | 1200 | 600-850 | 550-1250 | 45 | 6417×2880×3159 |

Mining and Quarrying: Heavy-duty vibrating feeders are commonly used in mining and quarrying operations for transporting bulk materials such as ores, aggregates, and minerals.

Construction: They find applications in construction sites for handling heavy-duty materials like gravel, sand, and concrete.

Steel and Metal Processing: Vibrating feeders are utilized in steel mills and metal processing plants to transport and feed raw materials, scrap metal, and slag.

Recycling: Heavy-duty vibrating feeders play a crucial role in recycling facilities for conveying and separating various recyclable materials.

Aggregate and Cement Industries: They are used in aggregate plants, cement factories, and concrete batching plants for handling aggregates, cement, and other bulk materials.

A vibrating tube-type feeder, also known as a vibratory tube feeder or tube conveyor, is a specialized type of vibrating feeder used for conveying bulk materials in a tube-shaped structure. These feeders are commonly used in industries such as food processing, pharmaceuticals, chemicals, and plastics, where gentle handling of materials and sanitary conditions are essential.

READ MORE

A hopper discharging system, also known as a hopper discharge system or hopper unloading system, is a mechanism used to efficiently and reliably empty or discharge materials from a storage hopper or bin. These systems are commonly used in various industries such as mining, agriculture, manufacturing, and bulk material handling.

READ MORE

Coal vibrating feeders are used to convey bulk materials from hoppers, silos, crushers, etc. in a wide range of applications including chemical, coal, foundry, quarrying and steel industries. The coal vibrating feeders produced by our company range in capacity from 100 tons/hour to 2500 tons/hour.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.