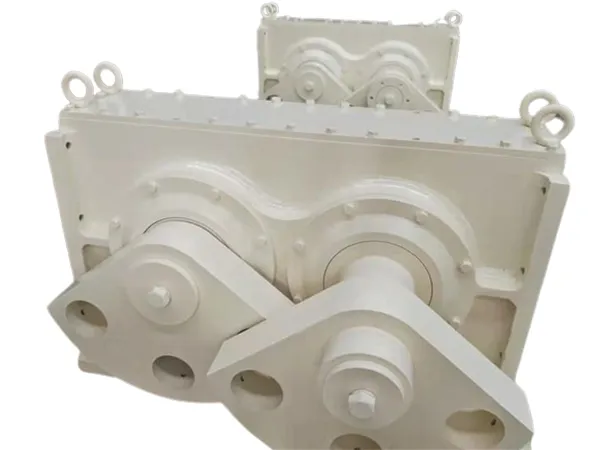

The DF401 series vibrating screen exciters are indispensable components used in vibrating screens for material screening, separation, sizing, and dewatering applications across various industries. Their robust construction, high efficiency, and adjustable settings make them well-suited for a wide range of industrial vibrating screen applications.

Features:

Robust Construction: The DF401 series vibrating screen exciters are typically built with sturdy materials and heavy-duty components to endure the demanding conditions of industrial environments.

High Efficiency: These exciters are designed for optimal energy efficiency, ensuring dependable performance while minimizing power consumption.

Adjustable Settings: Exciters within the DF401 series often incorporate adjustable settings for vibration intensity, frequency, and amplitude, empowering operators to tailor the vibrations to specific application requirements.

Low Maintenance: With sealed construction and minimal moving parts, DF401 series vibrating screen exciters generally necessitate low maintenance, leading to reduced downtime and operational costs.

Versatility: They are suitable for a wide array of vibrating screen applications across industries such as mining, aggregates, construction, recycling, and more.

Working Principle--The exciter can make the object get a certain form and size of vibration, so as to carry out vibration and strength test on the object, or calibrate the vibration testing instrument and sensor. The vibration exciter can also be used as an excitation component to form a vibration machine to realize the transportation, screening, compaction, forming of materials or objects, and tamping of soil sand and stone.

Application: it is mainly used for the replacement of vibration components on the vibrating screen of coal preparation plant/mineral processing plant, providing continuous and stable vibration force for the screening.

However, during the operation of mechanical equipment, noise and equipment wear and tear will inevitably occur due to vibration.

1. Shock Absorption

The above problems can be solved by installing shock absorber or rubber damping spring. Installation of shock absorber is a good way to eliminate noise and reduce wear, but it is worth noting that when selecting shock absorber, it is necessary to pay attention to the parameters of shock absorber and mechanical equipment to maintain the stability of amplitude during operation, so that the equipment is always in normal vibration state, and the running state of vibrator is normal. With the high frequency response of vibrator, it gradually decreases The effect of low noise will be more obvious.

The main component of rubber shock absorber is rubber block, which can be pressed into various shapes with different stiffness. Take the vibrating screen as an example, the rubber shock absorber can not only ensure the vibration work of the screen frame, but also make the screen frame pass through the resonance area smoothly and quickly, which is impossible for other shock absorbers. Moreover, because its impact stiffness is larger than the dynamic and static stiffness, it is conducive to reduce the impact deformation. In addition, the rubber metal shock absorber is easy to load and unload and has low noise.

2. Ensure the Stability of Excitation Source

At present, the development trend of linear vibrating screen at home and abroad are driven by double motor self-synchronous vibrator, its advantage is to eliminate the gear synchronizer and its lubrication device, simplify the structure and maintenance work, and facilitate the realization of three (standardization, generalization, serialization). Adopting this driving mode can greatly improve the stability and unity of the vibrating screen, thus greatly increasing the service life of the exciter itself.

In addition, it is necessary to optimize the shape of the exciter. Adopting optimization method to optimize the design of the main geometric parameters of the exciter can reduce the mass of the exciter itself and ensure that the maximum and minimum amplitude of the exciter are consistent with the required maximum and minimum amplitude, thus ensuring the stable and efficient working performance of the exciter.

By analyzing the working principle of the exciter, the general mathematic model of optimal design of the exciter is established. The main geometric parameters of the exciter are determined by the optimization meter, which not only reduces the product quality but also greatly improves its performance indexes.

3. Intelligently Monitor the Vibration Exciter

With the advent of industry 4.0 era, the intelligence of industrial Internet of things began to break through to a higher level. In the field of industrial equipment maintenance, predictive maintenance has become a key technical innovation. Predictive maintenance is developed from the concept of condition monitoring. "Condition monitoring" collects real-time information on the status of the parts being monitored; however, condition monitoring fails to predict machine interruption and wear consumption prospectively. In condition monitoring, vibration is one of the most important monitoring methods associated with mechanical failure!

HOT monitors the vibration exciter by installing the IOT sensor on it, and collects the operation data. The sensor data acquisition is completed, and the data is transmitted to the repeater by wireless transmission, which then sends the data to the local server for permanent storage through optical fiber and cable.

Then the data is uploaded to the cloud for permanent backup, and through the AI machine learning algorithm and model embedded in the cloud, the operation data of the equipment are analyzed, and the health status of the equipment is comprehensively evaluated.

Conclusion: HOT are able to provide high quality alternative exciters for all major brands. The self-developed exciter introduced by Beijing HOT Mining Technology Co., Ltd. uses imported bearings, which can perfectly replace more than 80% exciter brands on the market and realize cost-effective replacement. In addition, the intelligent predictive maintenance technology of vibration exciter independently developed can effectively improve the service life of vibration exciter, warn fault in advance, and further guarantee the production continuity of vibration screen.

The DF Series Vibrator refers to a range of specialized vibrators used in various industrial applications to generate controlled vibrations. These vibrators are designed for reliability, durability, and efficiency, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves.

READ MORE

NE Series Vibrators are versatile and reliable components used in a wide range of industrial applications to generate controlled vibrations for material handling, processing, compaction, and testing purposes. Their robust construction, high efficiency, and adjustable settings make them suitable for various industries requiring vibration-based solutions.

READ MORE

The FE series vibrator is a specialized component used in various industrial applications to generate controlled vibrations. These vibrators are designed to be reliable, durable, and efficient, making them suitable for integration into equipment such as vibrating screens, feeders, conveyors, compactors, and sieves

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.