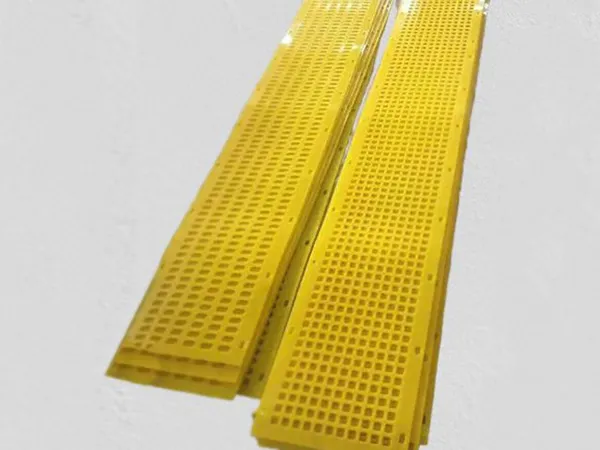

Flip flop screening panels are polyurethane elastomers that are formed by a casting machine at one time. The structural design of this polyurethane screen shows the characteristics of good abrasion resistance, good elasticity, high elongation at break and resistance to bending of the polyurethane elastomer.

READ MORE

The composite screen mainly solves the problems of low strength and short service life of ordinary woven mesh. It consists of surfing the Internet and supporting the Internet. It has high strength, rigidity and carrying capacity, and can effectively reduce vibration noise and increase the service life of the screen.

READ MORE

The high accelerations caused by the stretching of the screen pads and excessive expansion of the openings of the Trisomat vibrating screen deck result in virtually no clogging of the screen. Our experts will assist you in selecting the best screen materials and fixtures for your feed.

READ MORE

Vibratory feeder springs are critical components used in vibratory feeder systems to impart motion to the feeder tray or bowl, thereby conveying and controlling the flow of bulk materials. These springs play a crucial role in providing the necessary vibratory motion, absorbing shock and impact loads, and maintaining the stability and alignment of the feeder system.

READ MORE

Polyurethane screens and sieve plates are widely used in screening machines for metallurgy, mining, building materials, water conservancy, road construction, coal mines, metal and non-metal mines. Steel wire and steel plate are used in the screen as the reinforcing skeleton.

READ MORE

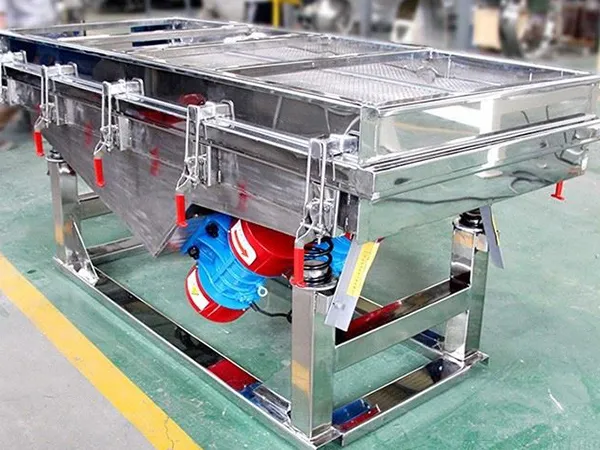

The integrated vibratory motors offer numerous advantages, including compact design, high performance, low maintenance, and energy efficiency. They are an integral component of vibrating equipment, contributing to efficient material handling and processing operations in industrial settings.

READ MORE

Vibrating screen shear spring is also called steel plate sandwich rubber shock absorber, it is wildly used in flip flop screen, or flip flow screen.Shear spring is the key to whether the screen can achieve tension and bounce.

READ MORE

Vibrating screen rubber springs are important components used in vibrating screens to absorb and reduce the shock and vibration transmitted from the screen box and deck to the support structure or frame. These rubber springs play a crucial role in improving the overall performance, efficiency, and lifespan of vibrating screens.

READ MORE

A vibrating screen cardan shaft is a crucial component in the operation of vibrating screens. It's responsible for transmitting rotational motion from the motor or drive system to the screen assembly. The cardan shaft is typically comprised of two universal joints connected by a shaft.

READ MORE

During the production of plastic pellets, especially during the start-up and shut-down phases, wrong cuts in the form of spikes or chains (often referred to as oversize) can occur. These bad particles interfere with further processing and must be separated from good particles.

READ MORE

The finger screen vibrating separators are effective solutions for screening and separating difficult-to-handle materials in various industries. Their unique finger design, high-amplitude vibration, and self-cleaning action make them well-suited for applications where conventional vibrating screens may struggle to perform effectively.

READ MORE

The five-deck stack sizer offers a highly efficient and versatile solution for fine screening applications in various industries. Its compact design, high screening efficiency, and low maintenance requirements make it an ideal choice for producers looking to achieve precise particle size separation and maximize production throughput.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.