Oversize separators for plastic pellets, also known as oversize screening equipment or pellet classifiers, are specialized machines used in the plastics industry to remove oversized or undersized particles from plastic pellet streams. Here are some features and advantages of oversize separators for plastic pellets:

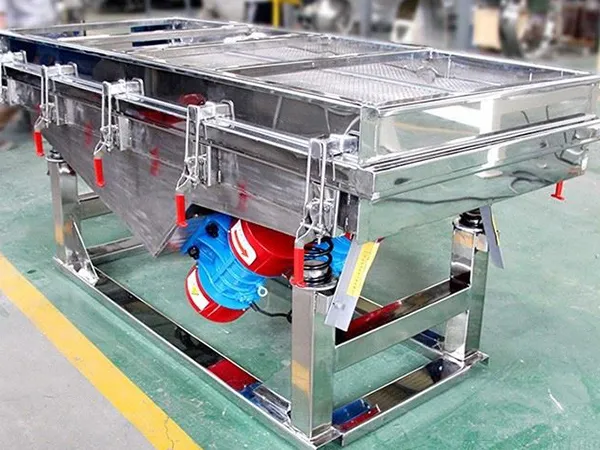

High Screening Efficiency: Oversize separators are designed to efficiently separate oversized particles from plastic pellet streams, ensuring that only properly sized pellets pass through. They employ various screening mechanisms such as vibrating screens, rotary sifters, or air classifiers to achieve high screening efficiency.

Accurate Particle Separation: These separators are capable of accurately separating particles based on size, ensuring consistent product quality and meeting specific size requirements for different plastic processing applications.

Customizable Configurations: Oversize separators for plastic pellets are available in various configurations to suit different processing requirements. They can be customized with adjustable screen panels, variable speed controls, and different screen or mesh sizes to optimize performance for specific types of plastic pellets.

Easy Integration: Oversize separators can be easily integrated into existing plastic pellet processing lines or used as standalone units. They are typically equipped with inlet and outlet connections for seamless integration with upstream and downstream equipment.

Durable Construction: These separators are built with durable materials and components that can withstand the abrasive nature of plastic pellets and the rigors of continuous operation. They are designed for long-term reliability and minimal maintenance requirements.

High Throughput Capacity: Oversize separators are capable of handling large volumes of plastic pellets, making them suitable for high-throughput screening applications. Their robust construction and efficient screening mechanisms allow for continuous operation at high feed rates, maximizing production output and efficiency.

Versatility: Oversize separators for plastic pellets are versatile and can be used for a wide range of plastic materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and more. They are suitable for screening pellets of different shapes, sizes, and densities.

Improved Product Quality: By removing oversized or undersized particles from plastic pellet streams, oversize separators help improve product quality and consistency. This ensures that only high-quality pellets are used in downstream processing operations, reducing waste and enhancing overall production efficiency.

Oversize separators, also known as oversize screening machines or oversize scalpers, are commonly used in the plastics industry for separating oversized or larger particles from plastic pellets. These separators play a critical role in ensuring the quality and consistency of plastic pellets used in various manufacturing processes.

Quality Control: Oversize separators are used for quality control purposes to remove oversized or irregularly shaped pellets from the production line. These oversized pellets can result from irregular pelletizing or molding processes and may negatively impact the performance and appearance of the final plastic products.

Protecting Downstream Equipment: Oversize pellets can cause blockages and damage to downstream processing equipment such as extruders, injection molding machines, and pelletizing lines. By removing oversized pellets before they enter the production line, oversize separators help protect downstream equipment from damage and reduce the risk of costly downtime and maintenance.

Improving Product Consistency: By removing oversized pellets, oversize separators help improve the consistency and uniformity of plastic pellets used in manufacturing processes. This ensures that the final plastic products meet quality standards and specifications, leading to improved product performance and customer satisfaction.

Optimizing Production Efficiency: Oversize separators help optimize production efficiency by reducing the need for manual sorting or reprocessing of oversized pellets. Automated oversize screening allows for continuous operation and minimizes production bottlenecks, leading to increased throughput and productivity.

Customized Screening Solutions: Oversize separators can be customized to suit specific requirements and applications in the plastics industry. This includes options such as adjustable screen configurations, variable speed controls, and different screen materials to optimize performance for different types of plastic pellets and processing conditions.

Environmental Benefits: By removing oversized pellets from the production line, oversize separators help reduce waste and improve resource utilization in the plastics industry. This results in cost savings and environmental benefits by minimizing the amount of material sent to landfills or recycling facilities.

Versatile Applications: Oversize separators are versatile and can be used for a wide range of plastic pellet materials, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and other thermoplastics. They are suitable for use in various plastic processing applications, including extrusion, injection molding, blow molding, and compounding.

Flip flop screening panels are polyurethane elastomers that are formed by a casting machine at one time. The structural design of this polyurethane screen shows the characteristics of good abrasion resistance, good elasticity, high elongation at break and resistance to bending of the polyurethane elastomer.

READ MORE

The composite screen mainly solves the problems of low strength and short service life of ordinary woven mesh. It consists of surfing the Internet and supporting the Internet. It has high strength, rigidity and carrying capacity, and can effectively reduce vibration noise and increase the service life of the screen.

READ MORE

The high accelerations caused by the stretching of the screen pads and excessive expansion of the openings of the Trisomat vibrating screen deck result in virtually no clogging of the screen. Our experts will assist you in selecting the best screen materials and fixtures for your feed.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.