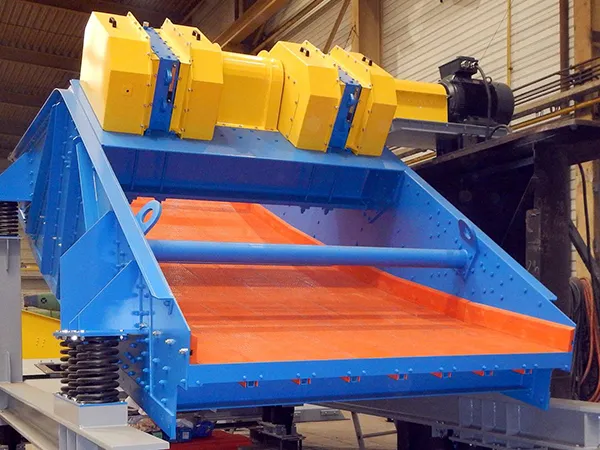

A banana vibrating screen is a specialized type of vibrating screen used in industries where high-capacity and efficient screening of bulk materials are required. This type of vibrating screen derives its name from the banana-like shape of its screen deck, which allows for a greater screening area compared to conventional vibrating screens.

Unique Shape: The most distinctive feature of a banana vibrating screen is its curved or banana-shaped screen surface. Unlike traditional flat or linear screens, the curved profile of the screen surface allows for better material stratification and increased screening efficiency.

Multiple Slope Angles: Banana vibrating screens typically feature multiple slope angles along the length of the screen deck. This design allows for gradual material flow and increased retention time on the screen surface, which enhances the screening process and improves separation efficiency.

High Capacity: Banana vibrating screens are known for their high-capacity screening capabilities. The combination of the curved screen surface and multiple slope angles facilitates the efficient handling of large volumes of material while maintaining effective screening performance.

Eccentric Mechanism: Like other types of vibrating screens, banana vibrating screens utilize an eccentric shaft with eccentric weights or unbalanced flywheels to generate vibration. This vibration mechanism creates a linear motion along the length of the screen deck, which helps to move the material across the screen surface.

Screen Deck Configuration: Banana vibrating screens typically consist of multiple screen decks stacked one above the other. Each screen deck may have a different slope angle, with the steepest slope usually located at the feed end to facilitate rapid material flow and efficient screening.

Applications: Banana vibrating screens are commonly used in industries such as mining, aggregate processing, mineral processing, and recycling, where high-capacity screening of fine or sticky materials is required. They are particularly well-suited for screening wet, sticky, or difficult-to-screen materials that tend to agglomerate or clog traditional flat screens.

Benefits: The unique design of banana vibrating screens offers several advantages, including improved screening efficiency, higher capacity, reduced pegging and blinding of screen openings, and better material stratification. These benefits result in enhanced productivity, reduced operating costs, and improved product quality for the end user.

Curved Screen Deck: The distinctive feature of a banana vibrating screen is its curved screen deck, which is designed to increase the screening area. This curved deck shape resembles the shape of a banana, hence the name. The curved design allows for longer screen surfaces within a limited footprint, resulting in higher screening efficiency and throughput.

Multiple Slopes: Banana vibrating screens typically have multiple slopes or inclinations along the length of the screen deck. This multi-slope design helps to improve the material stratification and screening efficiency by allowing the material to pass through different screening stages as it travels along the screen surface.

Screening Surface: The screen surface of a banana vibrating screen is typically made of wire mesh or polyurethane panels with various opening sizes. These screens are arranged in multiple decks to facilitate the separation of different particle sizes and ensure efficient screening.

Vibration Mechanism: Banana vibrating screens utilize a vibration mechanism similar to other types of vibrating screens, typically consisting of eccentric weights or unbalanced flywheels mounted on a shaft. When the motor rotates the shaft, it generates a linear motion in the screen deck, causing the material to move along the screen surface.

Material Separation: As the material is fed onto the banana vibrating screen, the larger particles travel to the top of the screen deck, while the finer particles pass through the screen openings and are collected as undersize material. This stratification of material helps to improve the screening efficiency and ensure accurate particle size separation.

High Capacity: Banana vibrating screens are known for their high-capacity screening capabilities due to their large screening area and efficient material stratification. They can handle large volumes of material with ease, making them suitable for applications requiring high throughput rates.

Versatility: Banana vibrating screens are versatile and can be used for a wide range of applications, including screening of dry or wet materials, scalping ahead of crushers or grinding mills, dewatering, and classification of various particle sizes.

Low Maintenance: Despite their complex design, banana vibrating screens are relatively low-maintenance machines. They are equipped with durable components and require minimal downtime for maintenance, ensuring continuous operation in demanding industrial environments.

ZSK eccentrics series linear vibrating screen is a new and efficient universal screening equipment, screen box trajectory which is approximately a straight line. This series of screen machine embodies most of the advantages of a biaxial linear screen, with the most extensive scope and application prospects.

READ MORE

A flip flop vibrating screen is a type of vibrating screen that utilizes the principle of elasticity to effectively screen and separate fine materials. This unique design creates a flip-flop motion during the screening process, which helps prevent material blinding and pegging.

READ MORE

Quartz sand screening equipment is essential in the processing of quartz sand to separate and classify particles of different sizes. These equipments ensure that the quartz sand meets the required specifications for various applications, including glassmaking, foundry work, ceramics, construction, and abrasives.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.