A gravity flow vibrating screen, also known as a gravity-fed vibrating screen or gravity-flow screener, is a type of screening equipment used to separate and classify bulk materials based on particle size. It operates on the principle of gravity to move materials through the screening process.

Sloped Deck Design: The gravity flow vibrating screen features a deck or surface that is inclined at an angle to the horizontal plane. This sloped design allows materials to flow downhill under the influence of gravity as they move through the screening process.

Material Feed: Bulk materials are fed onto the top of the inclined screen deck using a conveyor belt, chute, or other feeding mechanism. The material is introduced at the higher end of the screen and flows downward along the sloped surface.

Screening Process: As the material flows down the inclined deck, it encounters the vibrating screen surface. The vibration generated by the screen surface helps to loosen and stratify the material, allowing smaller particles to pass through the openings in the screen, while larger particles are retained on the screen surface.

Gravity-Assisted Movement: The combination of gravity and vibration facilitates the movement of materials through the screening process. Gravity ensures a continuous flow of materials down the inclined deck, while vibration helps to agitate and separate the particles, improving screening efficiency.

Adjustability: The angle of inclination of the screen deck and the amplitude and frequency of vibration can often be adjusted to optimize the screening process for different types of materials and desired screening efficiency.

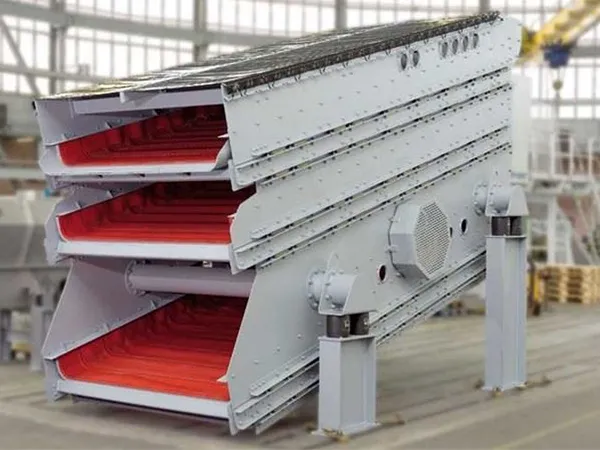

Screen Deck Configuration: Gravity flow vibrating screens may feature single or multiple screen decks stacked vertically. Each deck may have different screen openings or mesh sizes to facilitate the separation of materials into multiple size fractions simultaneously.

Application: Gravity flow vibrating screens are commonly used for screening bulk materials such as aggregates, sand, gravel, ores, and other granular materials. They are widely used in industries such as mining, construction, agriculture, and recycling.

Low Maintenance: Gravity flow vibrating screens are relatively simple in design and require minimal maintenance. They are equipped with durable components and are designed to withstand the rigors of continuous operation in industrial environments.

Sloped Design: Gravity flow vibrating screens are typically designed with a sloped deck or surface. The slope allows the material to flow downhill under the influence of gravity, facilitating the screening process. The angle of the slope can be adjusted to optimize the screening efficiency for different types of materials.

Vibration Mechanism: While gravity plays a significant role in the material flow, gravity flow vibrating screens may also incorporate a vibration mechanism to aid in the screening process. The vibration mechanism consists of an eccentric shaft with unbalanced weights or flywheels attached to it. When the motor rotates the shaft, it generates vibration that helps to agitate the material and promote efficient screening.

Openings in the Deck: The deck of a gravity flow vibrating screen is equipped with openings or perforations of various sizes. These openings allow the passage of particles smaller than the opening size while retaining larger particles on the screen surface. The size and shape of the openings can be customized to suit the specific screening requirements of the application.

Durable Construction: Gravity flow vibrating screens are constructed with durable materials such as steel to withstand the rigors of continuous operation in industrial environments. They are designed to handle heavy loads and abrasive materials without compromising performance or durability.

Low Maintenance: Despite their robust construction, gravity flow vibrating screens require relatively low maintenance compared to other types of vibrating screens. They are equipped with durable components and are designed to withstand the wear and tear of continuous operation. Routine maintenance tasks may include lubrication, inspection of screen panels, and replacement of worn or damaged components.

Versatility: Gravity flow vibrating screens are versatile and can be used for a wide range of applications, including screening of dry or wet materials, scalping ahead of crushers or grinding mills, dewatering, and classification of various particle sizes. They are commonly used in industries such as mining, aggregates, recycling, and construction.

Ease of Operation: Gravity flow vibrating screens are relatively simple to operate and require minimal operator intervention. Once the screening parameters are set, the screens can operate continuously with minimal supervision, ensuring efficient screening of materials with minimal downtime.

ZSK eccentrics series linear vibrating screen is a new and efficient universal screening equipment, screen box trajectory which is approximately a straight line. This series of screen machine embodies most of the advantages of a biaxial linear screen, with the most extensive scope and application prospects.

READ MORE

A flip flop vibrating screen is a type of vibrating screen that utilizes the principle of elasticity to effectively screen and separate fine materials. This unique design creates a flip-flop motion during the screening process, which helps prevent material blinding and pegging.

READ MORE

Quartz sand screening equipment is essential in the processing of quartz sand to separate and classify particles of different sizes. These equipments ensure that the quartz sand meets the required specifications for various applications, including glassmaking, foundry work, ceramics, construction, and abrasives.

READ MORECopyright © 2023 Xinxiang Zongyuan Machinery Equipment Co., Ltd. | All Rights Reserved.